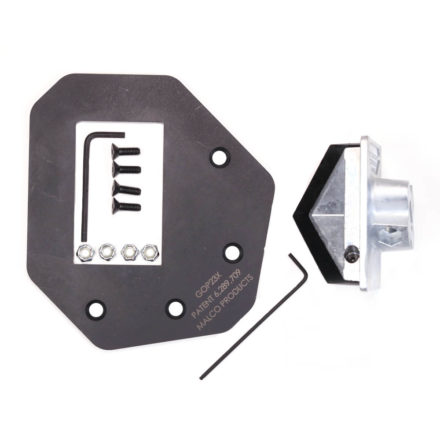

Gutter Outlet Punches

The Malco Gutter Outlet Punch and Dies make clean, accurate hole cuts in .032” (0.81 mm) aluminum gutter. Ample throat clearance allows these lightweight outlet punches to work over the front edge of gutter to quickly line up cuts. Convenient fastener holes are provided in the tool frame base for optional bench mount application. An easy ratcheting mechanism and angled punch-blade provide smooth cutting action. High carbon steel blades on punches ensure long service life and are also easily replaceable. Heat treated components and weather resistant finishes provide added tool strength and durability.

Malco Gutter Outlet Punch (GOT) Patent #6,289,709

FAQs

Q: Where do we get down spouts to work with our tool?

A: Your local gutter wholesaler would be able to supply you with the correct drop outlets for your particular needs.

Q: GOP34UK won’t release/sticking?

A: The punch must be fully seated before the gutter can be removed from the punch. The flaring that occurs in the last 1/8” of travel must be completed or the gutter will be very difficult to remove.

Q: Advantage of “X” style over “Rectangle”?

A: The “X” style outlet is preferred by some contractors as there is no need to use a drop. The tabs left by the punch are used to fasten the down spout to the gutter.

Others prefer to use a drop-in insert to ensure a more secure connection to the downspout.

Q: How do I remove the material from the punch?

A: The punch must be fully seated before the gutter can be removed from the punch. The flaring that occurs in the last 1/8” of travel must be completed or the gutter will be very difficult to remove.

Q: How do I center the punch in the die?

A: To position die, loosen the fasteners retaining the die, then fully seat the punch. Flip the tool over to review the alignment of the punch and die. Once centered, tighten the fasteners retaining the die. Note: The gutter may not release effectively from the punch if the punch is not centered on the die.

Q: How do I reinstall the drive rod?

A: See SL10684D GOP Chock Replacement Instructions

Q: What do I do if the GOT is slipping?

A: When the tool is slipping, verify the chocks are properly installed. If the chocks are properly installed but is still slipping replacement chocks are needed.

Q: What do I do if it won’t punch through the material?

A: First verify that the material you are attempting to punch is within the capacity of the tool. If you are having difficulty punching through the material, verify that the punch is centered on the die and that the chocks are working properly. Next confirm that the blades are sharp. Replacement blades are available and can extend the use of your GOT.

My Review for Gutter Outlet Punches

Testimonials

Shade