Modular Metal Bender, Wide, 215MM FS1W215

Your search for a light, versatile, and modular bending tool is over: look no further than the professional-grade Metal Benders by Malco!

Form 0-100° bends on straight or curved panels of any length on the jobsite, without waiting on wholesale rollformers. Metal Benders by Malco are designed for bends on flashing, roofing details, standing seam and exposed fastener metal roofing.

Malco’s Metal Benders are available in five single-station models:

- Narrow, 75mm (FS1N75)

- Narrow, 165mm (FS1N165)

- Wide, 165mm (FS1W165)

- Wide, 215mm (FS1W215)

- Wide, 365mm (FS1W365)

Narrow bearing stance models follow curved panels easily or form straight bends when needed. Wide bearing stance models provide more control for straighter bends. Both variations may be paired with a Bender Connector (FSC1) for a modular experience, allowing pros to customize their set-up in a one or two station configuration.

When using Malco’s Modular Benders, the FSLR metal roller accessory will provide a 2 mm radius when bending materials such as anodized aluminum or copper. The standard bender radius is .7 mm.

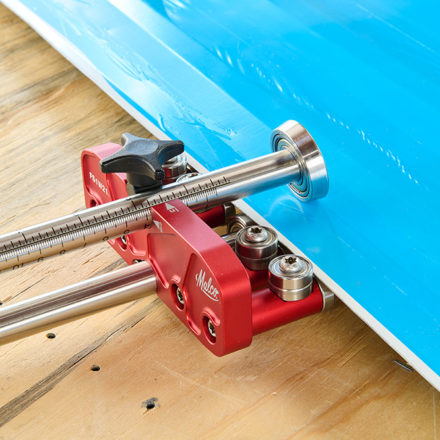

Malco’s Metal Benders are built tough with premium CNC aluminum and stainless-steel components for more durability and stability, allowing for more precise and higher quality bends.

Features

- Narrow bearing stance models (75 mm & 165 mm) follow curved panels easily or form straight bends when needed.

- Wide bearing stance models (165 mm, 215 mm and 365 mm) provide more control for straighter bends.

- Both narrow & wide variations may be paired with a Bender Connector (FSC1) for a modular experience, allowing trade pros to “freestyle” their set-up, in a one or two station configuration.

- Adjustable roller spacing accommodates a wide range of materials:

- Roller spacing adjustable from .5 mm – 1 mm

- Capacity of materials: 24 ga steel, 26 ga stainless steel, .040” aluminum, 20 oz copper, 1 mm zinc

- Exclusive angled roller doesn’t scratch material on 90° bends

- Optional 2mm Large Radius Accessory (FSLR) allows for “softer” bends in materials like copper, zinc, and aluminum.

- Quick setup, lightweight and highly portable, with a removable Handle (FSH2), sold separately, for compact storage.

- Premium CNC, aluminum and stainless-steel components are built tough, resist corrosion and make the product more stable for precise bends.

Specifications

| Catalog Number | Description | Bend Depth | Bend Range | Bend Radius | Material Thickness | UOM |

| FS1W215 | Bender, Single Station, 215mm (Wide) | 3/16” – 8 1/2” (5mm – 215mm) | 0° to 100° | 0.027” (.7 mm) | Adjustable 0.020” – 0.040” (0.5 – 1 mm) | EA |

| FSH2 |

Handle (sold separately) | — | — | — | — | EA |

| FSC1 |

Bender Connector | — | — | — | — | EA |

| FSLR | Large Radius Accessory | — | — | — | — | EA |

| FSBAG | Metal Bender, Bag | — | — | — | — | EA |

FAQs

Q: Are replacement parts available?

A: No, these products are very durable so it is unlikely you would need to replace any of the parts.

Q: What’s the difference between the narrow-body and the wide-body?

A: The narrow stance model is better for making curved or more detailed bends, but the wide stance design is better for making long, straight bends.

Q: What length do you recommend?

A: This depends on the bends you anticipate making. Larger tools can handle larger bends. Shorter depth tools can be considerably easier to make repetitive short bends with than a larger depth.

Q: How are these different than Malco’s ER3 3-station edge roller?

A: – The ER3 has a max bend depth of 4”, where these metal benders can bend depths up to 14 3/8”.

– Additionally, with the rollers, you can adjust for different thickness/different materials which our current ER3 roller cannot do.

– The low profile tapered roller of the Malco Metal Bender allows you to bend mechanical lock standing seam profiles which the ER3 is not capable of making.

-Malco’s Metal Benders are also lighter (in most configurations) than ER3, and the modular nature of the product means they are a little more versatile, too, for tackling different types of jobs.

Q: Can the benders connect to Malco’s ER3 product?

A: No. However, pairing 2 single station tools with a connector (FSP1) will allow use similar to the ER3 by using the tool either as a 2-station tool or as a 1 station tool. Easily switching between tasks.

Q: What would you recommend I purchase?

A: It depends on what you are trying to bend (curves or straight lines), size of the bends, and frequency of use.

Frequent users would probably be better off buying a fixed two-station Metal Bender for long runs, or a single station bender for small runs and curves. Get both if they anticipate both situations.

Less frequent users could benefit from the modular design. Buy two single-station benders and a connector. This would be a cheaper option than buying a one- and two-station bender and allows for the ultimate in jobsite flexibility.

Q: What’s the difference? / What makes yours’ better?

A: -Malco’s Metal Benders are made with premium CNC aluminum and stainless-steel components which not only makes the product more durable, but also more stable and resistant to movement, allowing for more precise bends, or higher quality bends without scratches.

– Allowing the user to adjust the rollers for different thicknesses and materials.

– Optional 2mm radius roller to allow for “softer” bends for materials like copper, zinc, and aluminum which can have problems with tighter bends.

– Angled roller so you do not scratch the material on a 90-degree bend — something most current benders on the market do not have.

– Modular tools allow single station tools to be paired with a connector allowing for best-in-class flexibility.

Q: Is there a special technique?

A: The trick to making a nice straight bend on metal with the metal benders is to start with a straight cut edge on the material you will be bending. Because the metal benders tracks along the edge of the material to be bent it is important to have a straight cut. The technique that works the best to prevent rippling of the material is to not bend the material up too quickly. It is better to put light pressure on the tool and make multiple passes bending the material up about 10-20 degrees on each pass. For a bend to 90 degrees, you should plan to run the tool back and forth at least 5 times.

Another tip is to roll the bender across the entire length of material prior to adding any bending pressure. This will create a small crease that the rollers will follow to help the bender track straight.

Q: What type of bends are achievable?

A: The metal benders can bend straight bends of an infinite length up to 100 degrees, but most people will bend up to 90 degrees in the field. It is also capable of bending a 100-degree leg on a curve with radius of 17 feet or larger. It will work on tighter curves if it is not necessary to bend to a full 100 degrees, attempting to bend to a full 100 degrees on a tight curve will result in ripples on the bent-up material.

Q: What gauge material will it bend?

A: The metal benders by Malco are adjustable thickness tools allowing them to work on a variety of thicknesses with professional results. See the capacity table for the thickest material we recommend bending for each material type.

Q: What materials does that translate to?

A: The gauge is a measure of the thickness of the metal, metal thickness increases as the gauge numbers decrease.

Steel:

-

- standing seam roofing, coil stock material, commonly used for trim and flashing

- 29 gauge is .014″

- 28 gauge is .016″

- 26 gauge is .018″

- 24 gauge is .025″

- standing seam roofing, coil stock material, commonly used for trim and flashing

Copper:

-

- 26 gauge is .016” – commonly used for backsplashes, range hoods as well as roofing

- 24 gauge is .022” – 16-ounce copper sheeting is often referred to as “roofing copper” or “roofing flashing.”

- 22 gauge is 0.027” – 20-ounce copper sheeting is often used for roofing and gutters

Zinc:

-

- 1mm

Aluminum:

-

- 0.040”