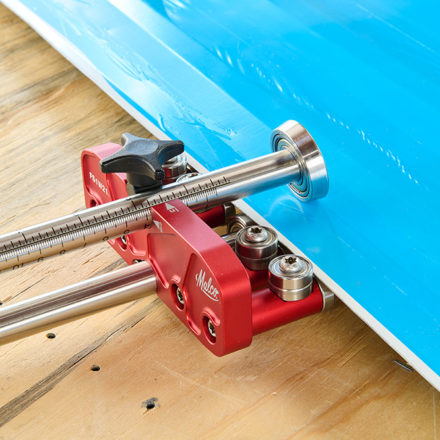

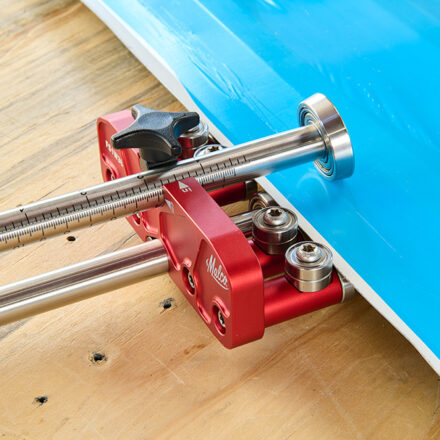

Power Assisted Metal Seamer, 2″ FSXS2

Malco’s power-assisted seamers are the fastest seaming machines on the market, making them the perfect hand-held equipment for effortless seaming. Similar to the FSXS, the FSXS2 is used to mechanically seam panels on standing seam installs. Please note that the 2 inch seamer will only do a 2-stage lock. Users will also notice a blind hole for a tether, which allows users to tie off the tool as a precaution. Simply attach the power-assisted seamer to your cordless drill and go.

The Malco Power Assisted seamer comes packaged in a premium IP 67 case with custom foam inserts to ensure the safe storage of your seamer. Designed for roofing professionals working with Stainless Steel, Steel, Aluminum, Copper, and Zinc materials.

You can confidently quote repair and retrofit jobs, knowing that the material your customers want on their roof is something you can install.

To see the replacement part FSXS2RPDW, click here!

Features

- Mechanically lock standing seam panels in less time, while working safer, and offering your customers more profiles.

- Seam 2 inch standing seam panels on a 2-stage lock.

- Closes 2-stage mechanical lock panels.

- FSXS2 Seamer is equipped with safety lanyard hook up point using 5/16-18 UNC thread.

- Black housing to differentiate from FSXS.

Specifications

Catalog Number |

Description |

Profile Size in. (mm) |

Steel Capacity |

Aluminum Capacity (mm) |

Copper Capacity (mm) |

Stainless Steel |

Zinc |

| FSXS2 | Standing Seam Seamer, 2″ | 2″ Double Lock (50.8mm) | 22 ga. | .040″ (1 mm) | 20 oz. (591 cm) | 26 ga. | .040″ (1mm) |

| FSXS2RPDW | Wheel Replacements | — | — | — | — | — | — |

FAQs

What do I do if I am having trouble getting the tool to drive itself forward?

If the roof is wet, the tools will not drive consistently. You will need to dry the roof before seaming the panels.

Other typical issues with the seamer are often related to the seaming pressure adjustment to little pressure, will result in the tool failing to feed while too much seaming pressure will lead to deformed or crushed finished seams.

- Please see the:

What should I look at if the drive wheels wore out after I only used the seamer a short time?

Verify seaming pressure knobs are adjusted properly to obtain the desired finished seam.

Over tightening these adjustment knobs can result in unnecessary contact forces on the drive wheels resulting in premature wear.

Premature drive wheel failures are often related to attempting to seam panels in the incorrect direction. The drive wheels need to ride along the vertical leg of the panel and the form wheels need to be positioned to close the open seam.

We recommend using factory original replacement drive wheels.